Manufacturing

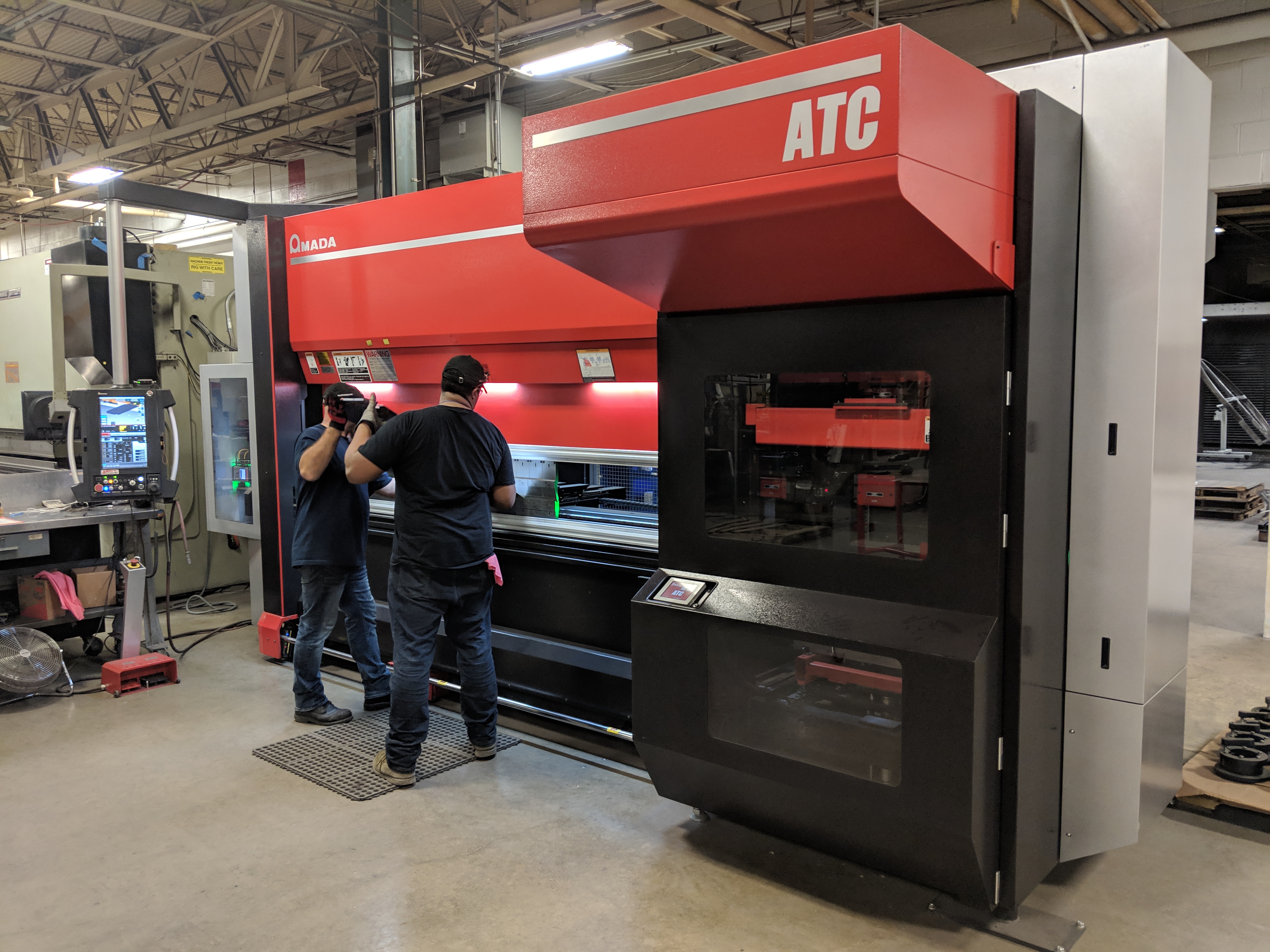

TRITON DEFENSE operates a 52,000 ft. Facility in Hollywood Maryland outfitted with the latest cutting edge equipment available. TRITON has honed its innovative processes for over 25 years with a tremendous heritage of precise manufacturing talent which makes up our DNA; our company is home to some of the most talented craftsman and creative minds in the industry. We have forged our own path with technology to create a culture that strives to build the highest quality products found in the industry today.

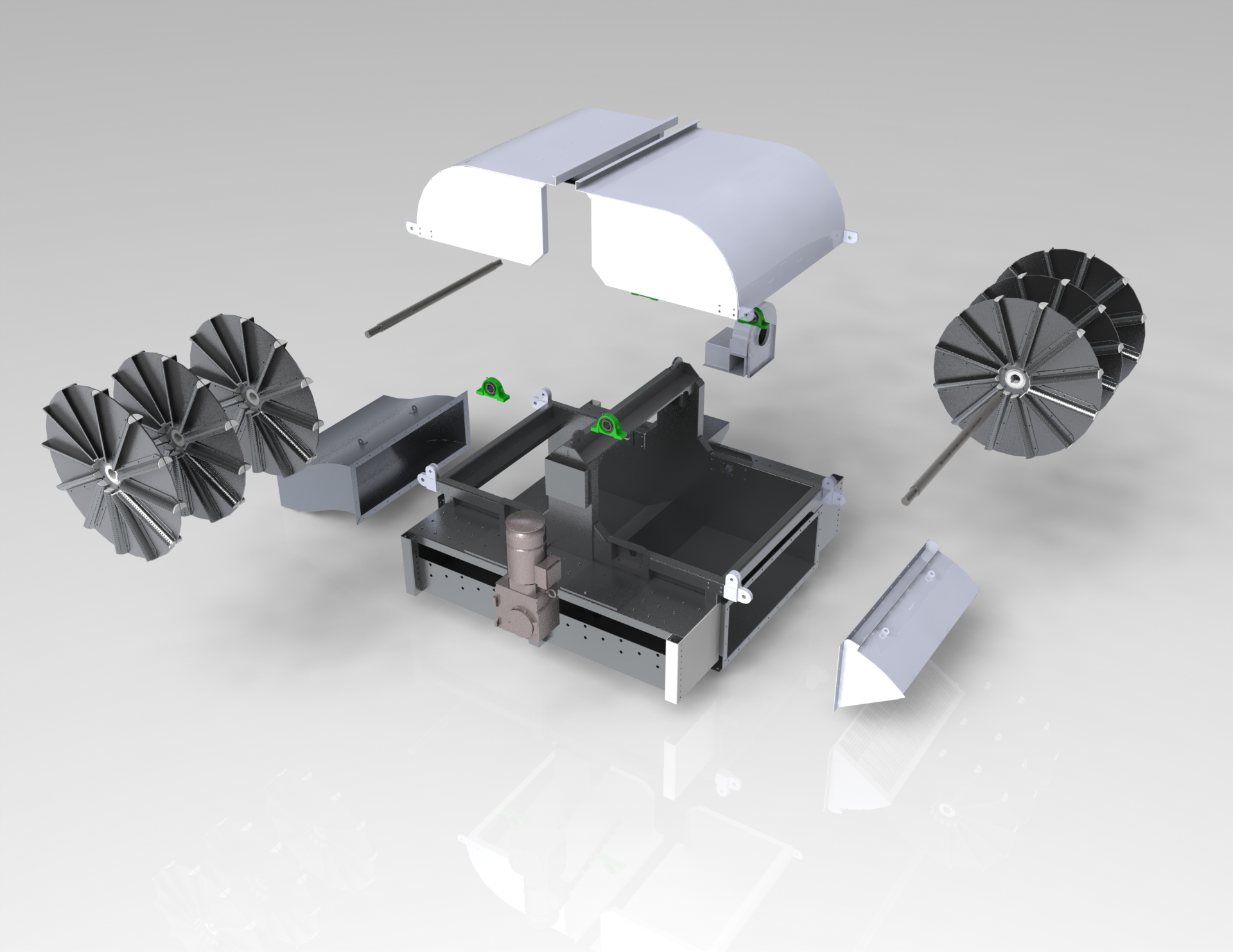

We are a Model-based enterprise (MBE). A term used in manufacturing, to describe a strategy where an annotated digital three-dimensional (3D) model of a product serves as the authoritative information source for all activities in that product's lifecycle.

We live in a virtual manufacturing world here at TRITON; every assembly, product, and part starts as a 3D model in our Engineering and Design Department. Each specific component is looked at individually, programmed, virtually inspected and the process checked throughout its life has become the system we intentionally developed to provide quality throughout the manufacturing process.

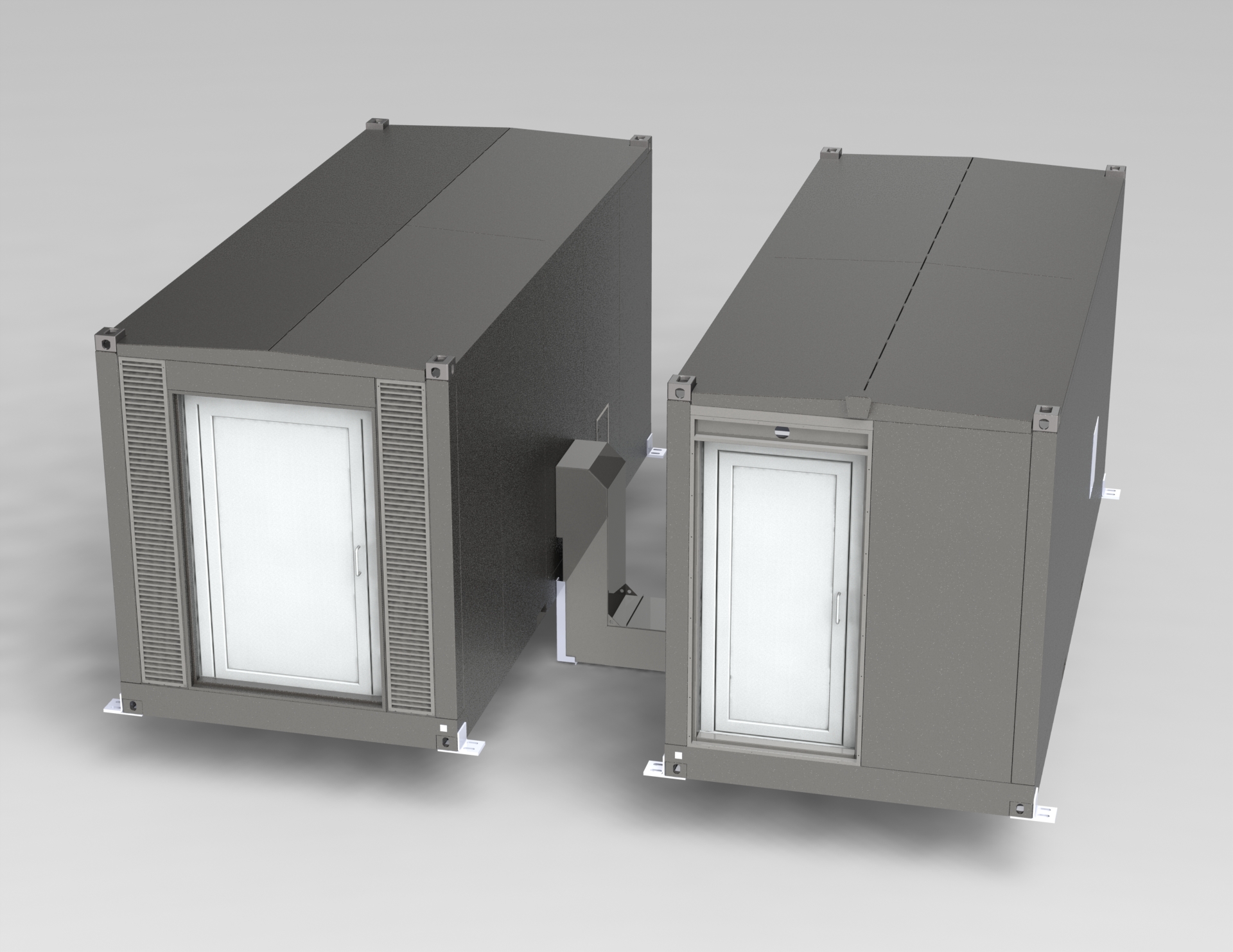

We offer a complete Fabrication Facility with Design and Engineering, Laser cutting, Laser Tube cutting, Waterjet cutting, Forming, Roll Forming, Welding, Machining, Assembly, Finishing, Integration, Electrical, Plumbing, Interior Finishes, HVAC, CBRN Air filtration, HEMP Testing, Quality assurance program ISO 2009-2015

NaN:NaN

We want and appreciate your business; although HEMP Protected Modules is our primary focus, we have OEM Partnerships in similar areas of Defense. We build clients product and often manufacture Jobshop type work as well for a select group. Please take time to visit us; we are happy to be of service.